Warehouse Management System

Manage all your inventory digitally and in real time with the assistance of mobile technology

Our Mobile App

Warehouse management System

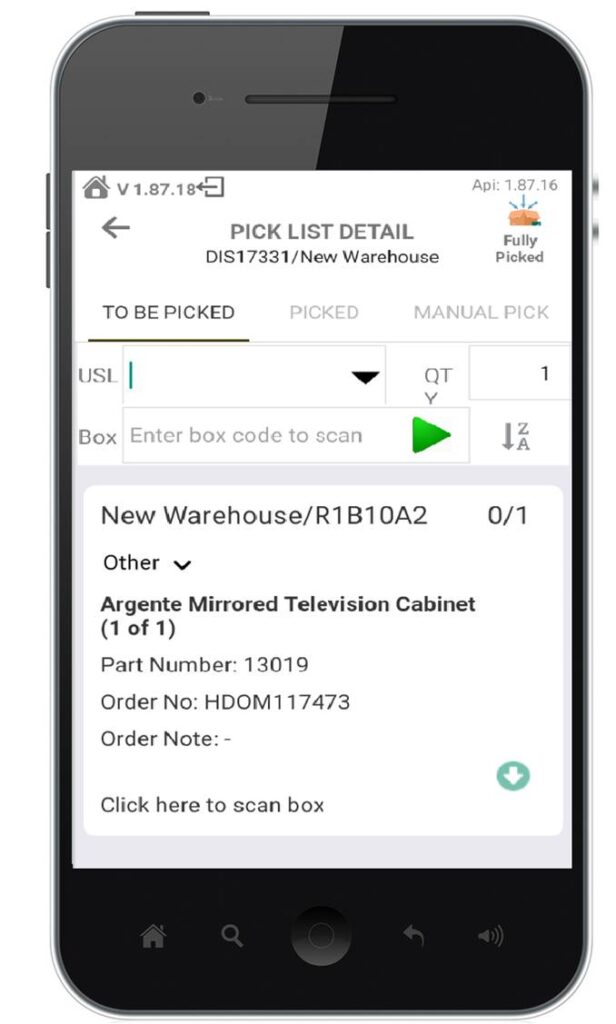

Picking

Using Scanning facilities picking has never been easier.

Our picking module features include:

- Different sorting options allows you to sort by customer order, by product, or by the most efficient route around your warehouse.

- If an item isn’t in the suggested location you can search alternative locations in your warehouse to pick from

- If there has been a clerical error, you can stocktake the item into a location there and then to allow you to continue the pick, without ever leaving the picklist.

- Items being picked for a replacement order will be flagged, to allow users to ensure extra care I taken or the item is checked before sending out to the customer

- Print labels from the picklist to place on items leaving the warehouse

The above will all contribute towards saving time and money when it comes to picking your delivery run.

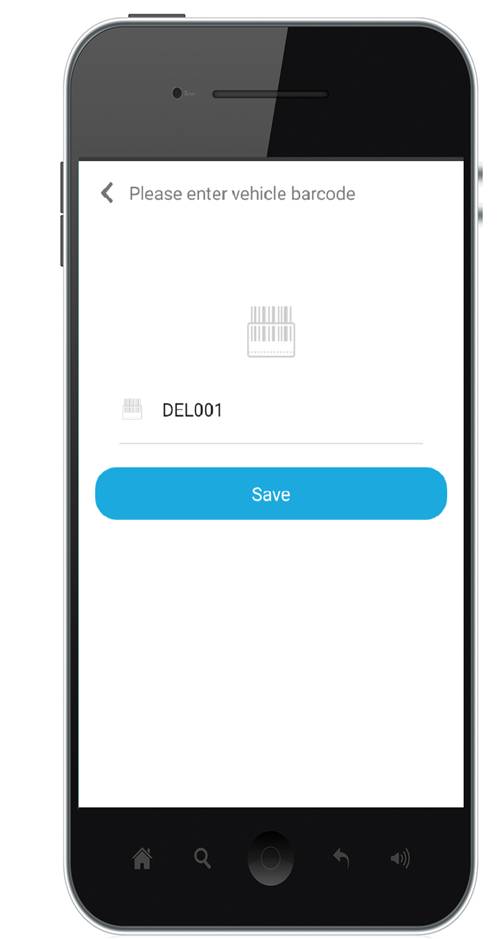

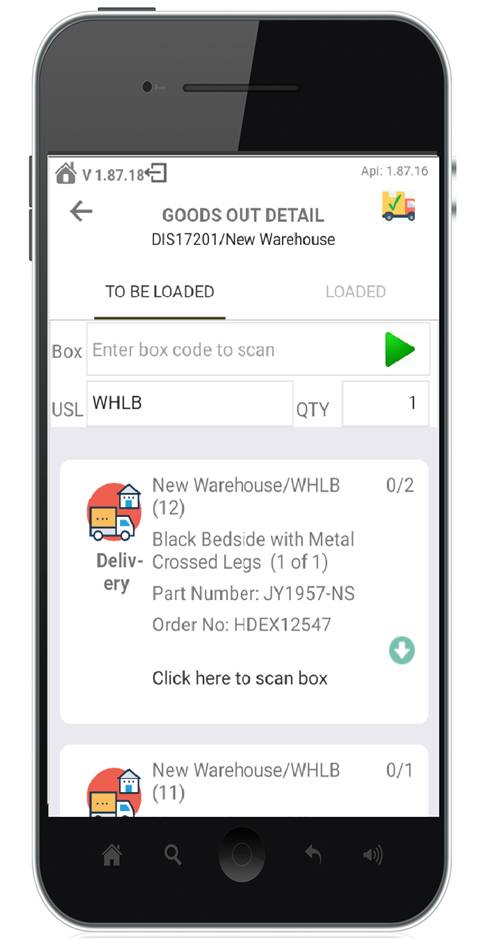

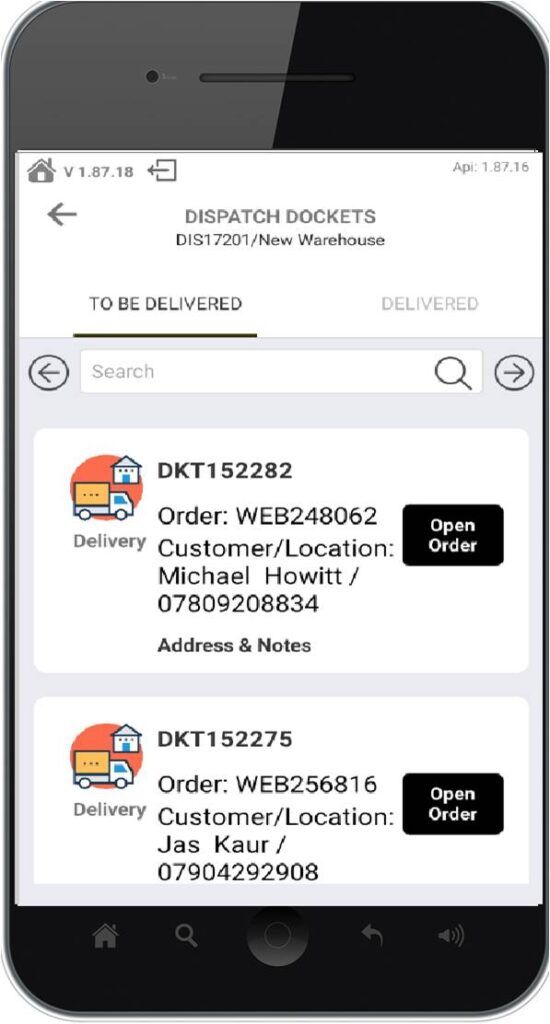

Loading Trucks

Once picking is completed you can then load the products to the truck.

This is an optional step and can be auto loaded and bypassed when completing the picking.

Some users prefer to include this as two step process for increased accuracy and ensuring all items picked actually make it to the truck

- At the loading phase users are prompted to choose their vehicle by either entering the registration number, or scanning the vehicle barcode

- Loading will be arranged in reverse order, so that the last order loaded on the truck, is the first order to be delivered

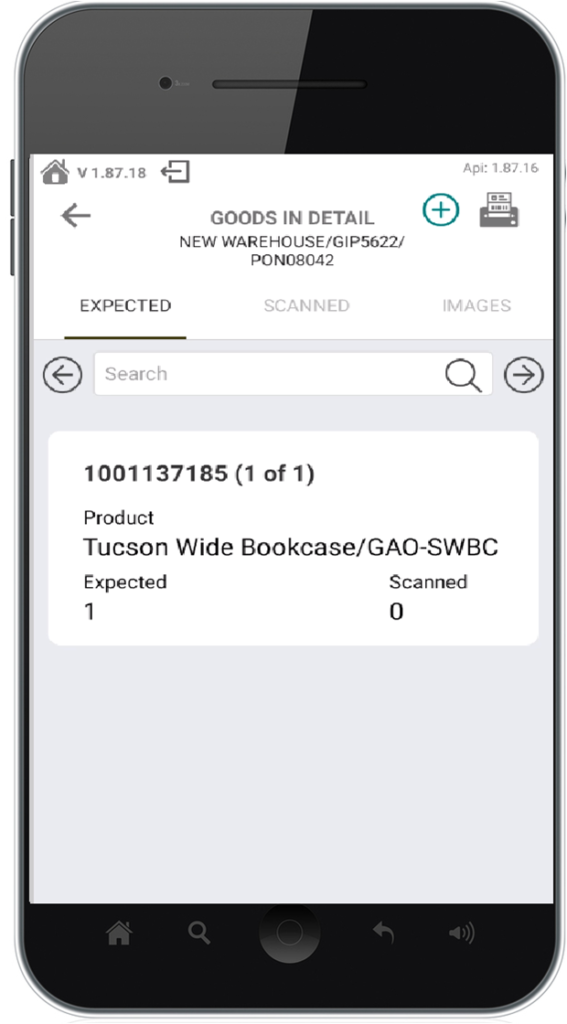

Receiving Inventory

Receiving goods in from Purchase orders is simple, in this module you can:

- Convert a purchase order into the ‘goods in’ status

- Scan goods that have arrived

- Scan in any additional items not expected (flagged at time of finalising the stock adjustments)

- Print barcode labels for goods

- Print labels for customer special orders which can include name and order number

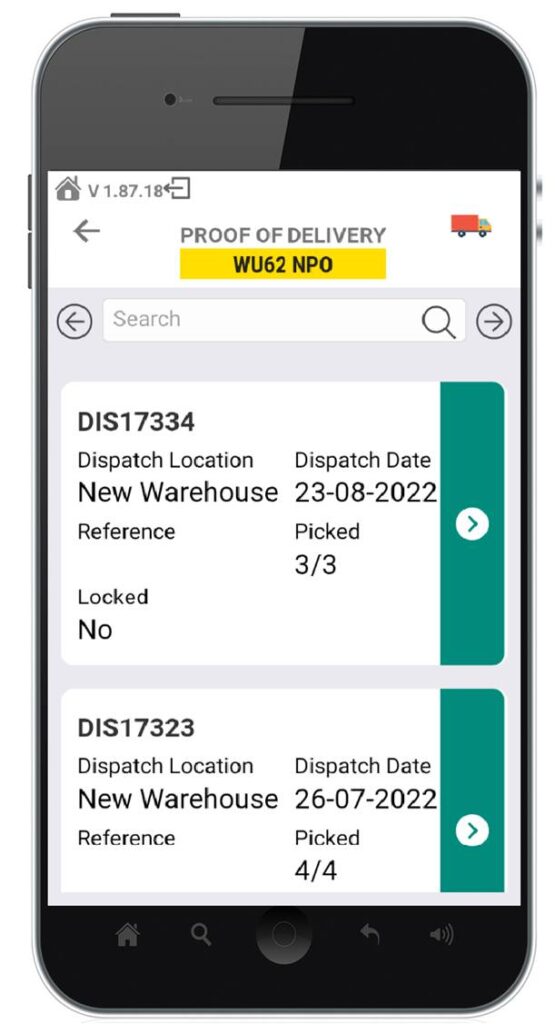

Proof Of Delivery

Proof of delivery Can be used as a standalone module if picking and loading processes aren’t required.

This module incorporates the following features:

- Routing you to the customers address organized for the most efficient route

- Capturing customers written digital signature or a photo signature of delivery

- Report any faults or failed delivery, reschedule and capture photo evidence

Mark goods as delivered in real time.

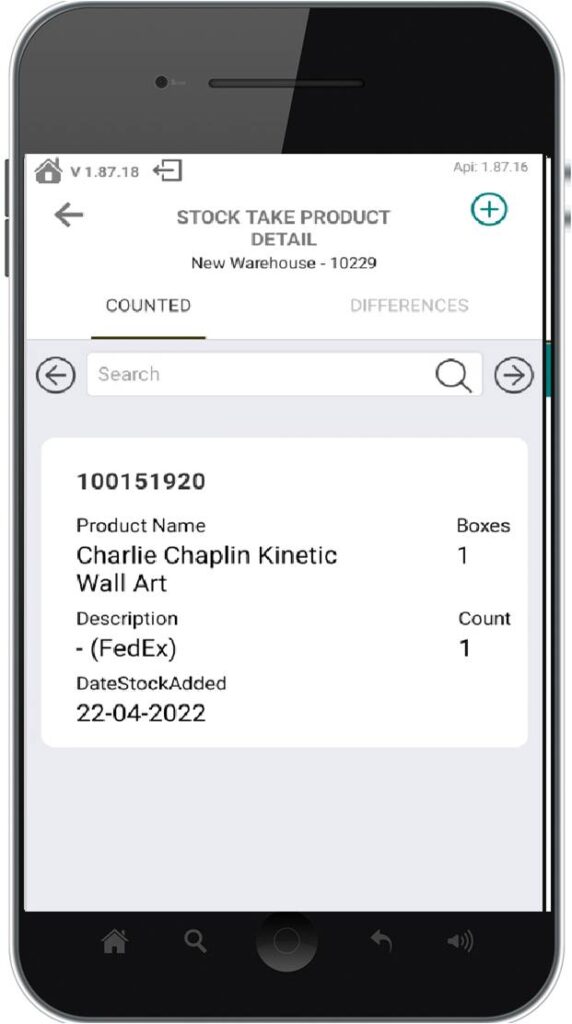

Stock Taking

Our stocktaking module allows for stocktaking at multiple levels and allows reporting on discrepancies

- Stock take/ inventory count for stores at a simple level using stock level only and item barcodes

- Stock take/inventory at a warehouse level for boxes and bin locations (row 1 bay 6 etc) this will count box 1 of 2, box 2 of 2 etc and give a total amount of COMPLETE product

- Reporting on discrepancy at stock location and unique bin locations

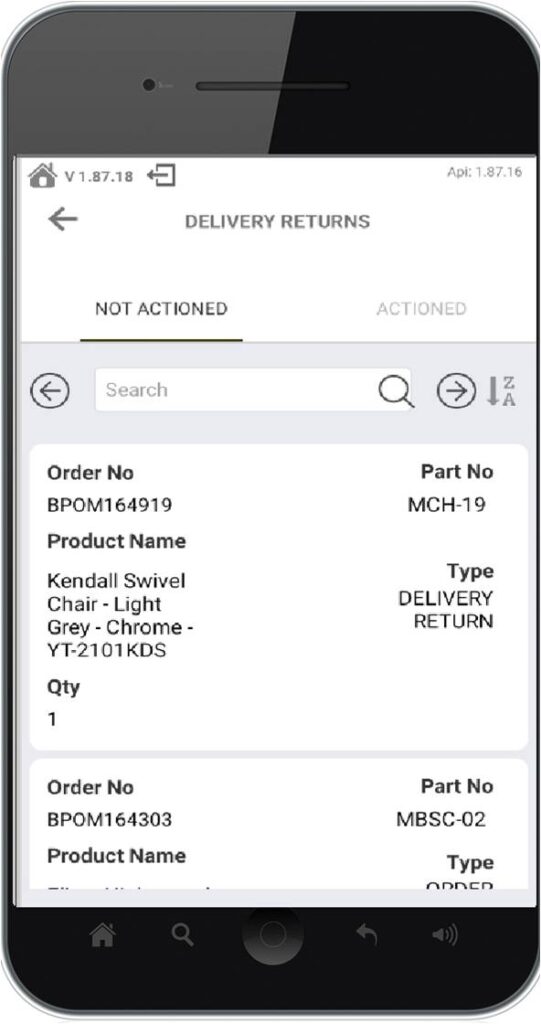

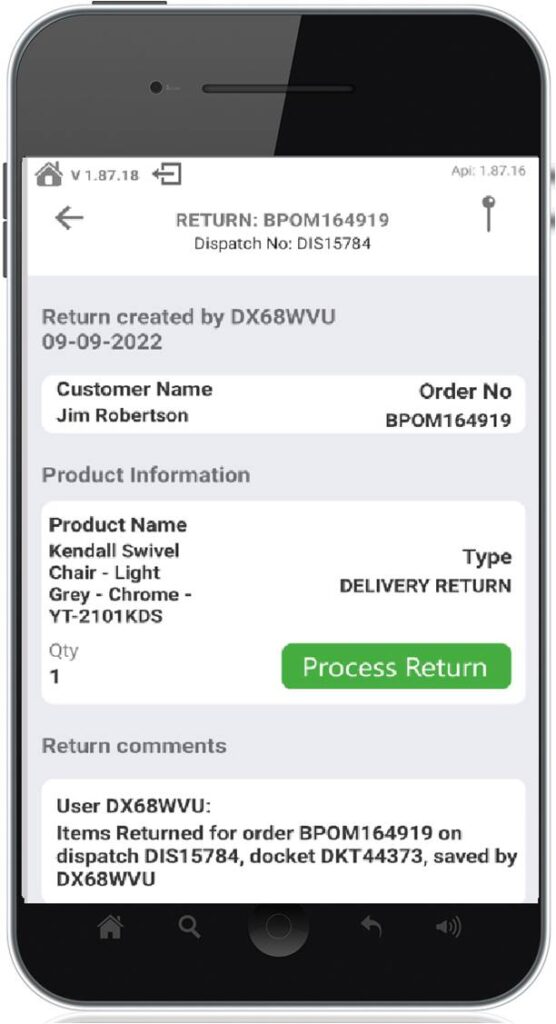

Returns

- Easily see at a glance orders that need to be returned to stock either A) from an order cancellation

B) collecting from customer

C) a failed delivery - View orders to returned and those already actioned

- Scan the items back into stock or to a damages/returns location

- Manually return goods if scanning and barcoding isn’t in use

- View notes and comments for additional information on why the goods are being returned

- Scan the goods into a bin location within a warehouse/store

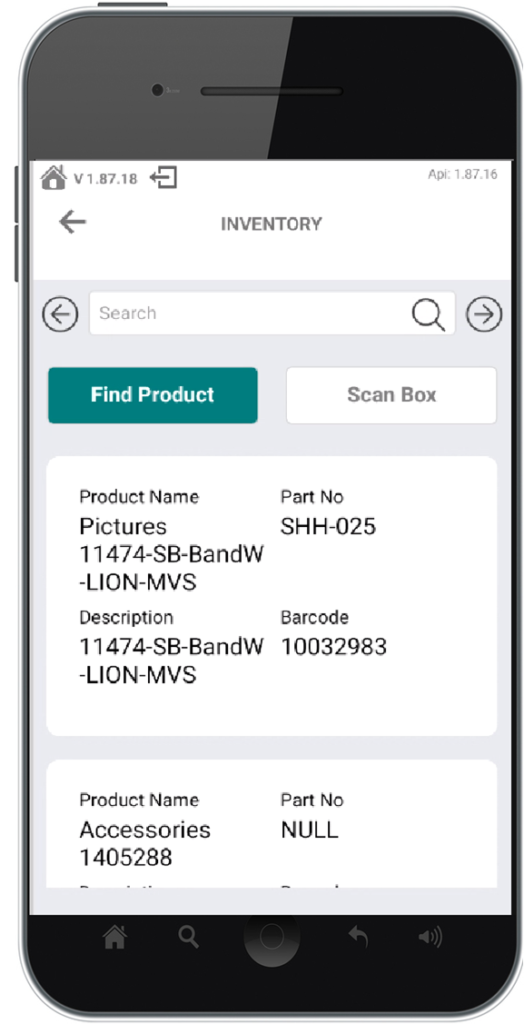

Inventory Management

- View stock/inventory quantities across one or many locations

- Retrieve additional information such as item code, barcode number, dimensions and more

- View images of your product

- Know where your products are in your warehosuses and stores

- Cehck with bin location the products and boxes are in

Digitalise your warehouse with Ordorite Warehouse management System

Ordorite Mobile apps have been designed with efficiency and usability in mind for warehousing and delivery experts.

Our Mobile App will enable you to quickly and with ease:

Proof of delivery :

Warehouse Management

Ordorite’s system accounts for warehouse management tools and techniques such as barcoding & box management, stock taking & movement and product lifecycle tracing.

By some estimates, item-level tagging, when implemented properly, can increase inventory accuracy from 63% to 95%

Human error is the top issue in 46% of warehouses

1 out of 3 businesses tend to delay shipments because of selling unavailable products to customers

You have questions,

We have answers

Want to know more about Ordorite?